Metal panel dent repair is a crucial skill for auto body services, enhancing vehicles' restoration quality and aesthetics. It involves precise manipulation of metal under pressure and heat to minimize distortion and remove dents effectively. Skilled technicians use various tools from manual hammering to laser technology, demanding precision in handling different metals. The science behind it considers metallurgy and specialized equipment for accurate measurements. Effective repair addresses both visible dents and structural integrity, ensuring top-quality car repair services. A superior metal panel dent repair restores structural integrity, secures long-term aesthetic value, uses OEM or certified parts, and conducts thorough inspections for a flawless finish, preventing future damage.

In the realm of automotive aesthetics, metal panel dent repair stands as a crucial skill, enhancing vehicles’ overall look. A quality job transcends mere removal of dents; it entails precision, expertise, and attention to detail. This article delves into the intricacies of exceptional metal panel dent repair, exploring techniques, materials, and quality control measures that ensure longevity and restore vehicles to their pristine condition. Uncover the science behind effective dent removal and understand why these practices are vital for satisfying results.

- Understanding the Importance of Precision in Metal Panel Dent Repair

- The Art and Science of Effective Techniques for Dent Removal

- Ensuring Longevity: Materials, Quality Control, and Finishes in Metal Panel Restoration

Understanding the Importance of Precision in Metal Panel Dent Repair

In the realm of auto body services, metal panel dent repair stands as a crucial skillset that can make or break the quality and aesthetics of a vehicle’s restoration. Precision is the cornerstone of this craft; every subtle movement and calculated step contributes to achieving flawless results. The art lies in understanding how metal behaves under pressure and heat, and employing techniques that minimize distortion while effectively removing dents and dings.

A quality metal panel dent repair job transcends mere removal of physical damage; it involves meticulous attention to detail, ensuring the panel returns to its original shape and alignment. Skilled technicians utilize a combination of specialized tools, advanced technology, and expertise to achieve this. The end goal is not just to fix the visible imperfection but to preserve the overall integrity and longevity of the vehicle’s body, making it an essential aspect of top-tier car repair services.

The Art and Science of Effective Techniques for Dent Removal

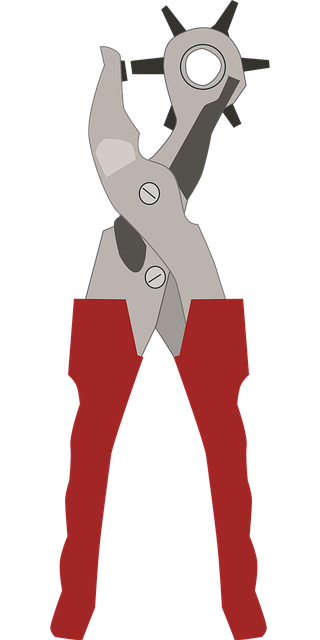

The art of metal panel dent repair lies in a delicate balance between science and skill. It’s not just about removing the visible deformity; it’s about understanding the underlying structure and mechanics of the metal. Technicians employ a variety of techniques, from manual hammering and bending to advanced tools like pneumatic hammers and laser technology, each with its own precision requirements. The science behind it involves knowledge of metallurgy, knowing how different metals behave under stress, and utilizing specialized equipment for accurate measurements and adjustments.

Effective dent removal is both an art and a precise science. It demands patience, attention to detail, and the ability to adapt techniques based on the severity and unique characteristics of each dent. Auto body repair experts must also consider the impact on the overall structure and integrity of the vehicle, especially when dealing with complex frame straightening issues. This multifaceted approach ensures that not only is the metal panel restored to its original condition but also that any associated structural damage is addressed, providing top-quality car repair services.

Ensuring Longevity: Materials, Quality Control, and Finishes in Metal Panel Restoration

A quality metal panel dent repair job ensures longevity and preservation of the vehicle’s aesthetic appeal. The choice of materials is paramount; using original equipment manufacturer (OEM) or certified parts guarantees a precise match in terms of color, texture, and strength. These materials should be resilient to corrosion and capable of withstanding future environmental stressors, ensuring the repaired area lasts for years to come.

Quality control measures, including meticulous preparation, proper painting techniques, and careful finishing, are vital. Skilled technicians perform surface preparation to ensure paint adheres perfectly, avoiding future peeling or chipping. The application of high-quality paints designed specifically for metal panels, followed by a thorough inspection, guarantees a flawless finish that matches the rest of the vehicle. This attention to detail not only enhances the car’s appearance but also safeguards against future car damage repair and auto collision center incidents, extending the life of the vehicle’s exterior.

A quality metal panel dent repair job is a harmonious blend of precision, advanced techniques, and meticulous attention to detail. By combining art and science, professionals achieve not just visible restoration but also ensure the longevity of vehicle panels through top-tier materials and stringent quality control measures. This comprehensive approach guarantees that each repair reflects excellence, restoring both the aesthetic appeal and structural integrity of metal panel dent repairs, thereby enhancing customer satisfaction in the process.